Facilities management is one of the most time-consuming professions there is. Between keeping tabs on employees, monitoring the budget, and everything that else that happens to fall into your lap, it can be hard to remember some maintenance issues that are out of sight and out of mind. Make sure these are taken care of so your workplace continues to run efficiently and safely.

HVAC

A creeping energy bill might be the only sign of an HVAC system that needs a little TLC. It’s easy to pass off as a simple change in weather conditions. When your HVAC system isn’t running at its very best, not only can it get pricey, but it can also go completely out in the first blizzard or heat wave of the season. It’s best to practice preventative maintenance each spring and fall.

If you have an outdoor cooling unit, do a visual inspection to make sure the fans are running (quietly), the unit is clear of dust and debris, and the connections to the building are sound.

Indoor heating units can have more complications. Each season, you should check for gas leaks, inspect your connections, replace air filters, and clean the blower assembly.

These are only a handful of items that you should check off your HVAC maintenance list. Trane has a great comprehensive resource for heating and cooling preventative maintenance. If anything you see is beyond your control or expertise, immediately call in a professional.

Damp Basements (and Leaky Windows)

People tend to ignore basements. It’s the basement’s fault that they’re damp, dark, and spider safe-havens! While the basement might only be where old office furniture and file cabinets end up, it’s worth checking in on occasionally. If your building has a basement and is in a region with high humidity, there’s a chance your basement is actually the perfect breeding ground for mold. Mold only needs two things to live: a comfortable temperature and moisture.

If you find scattered visible evidence of mold, there’s no reason to panic and call in the professionals, which is a lot of people’s knee jerk reaction to seeing those pesky little spores.

First, clean the area thoroughly. Unfortunately, even potent cleaning products like bleach don’t kill mold, so you can’t stop there and call it a day. The most important step in remedying your mold issue is to control the humidity. In a basement, it could be as simple as setting up a few dehumidifiers and making it a habit to empty the tanks when they fill up. The amount of water they collect is kind of amazing.

Mold can also grow as a result of a water intrusion. In this case, try to clean up the water within the first 48 hours. A prompt response will reduce the chance of mold growth.If the water intrusion goes unnoticed, sop up all the water, thoroughly clean the wet surfaces, and push the humidity from the room.

If you suspect mold spores in your basement (or another nook in your building) but cannot see anything, you can purchase DIY Mold Testing kits from MyMoldDetective.com.

Chipping Paint

Buildings constructed before 1978 can contain lead-based paint. Replacing lead-based paint isn’t necessarily “routine” maintenance item, but repairing chipped paint should be on your radar so issues don’t arise in the future and more routine repainting doesn’t become a major pain.

Lead paint repairs also arise during renovations and remodel projects, which is when you should call in the professionals. Tackling the project yourself can put you and your workers at risk of lead-related health issues.

Professional painters and contractors may remedy your issue by recommending replacements for windows, doors, and trims. If that isn’t an option, they can wet scrape the lead paint carefully from your walls or encapsulate everything with a special adhesive coating.

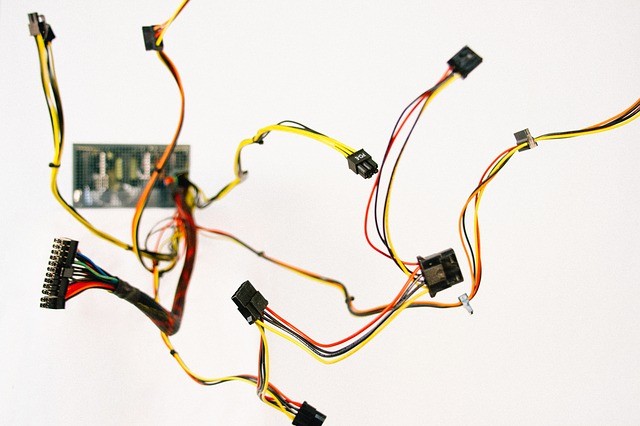

Wiring

“Between 2010 and 2014, U.S. municipal fire departments responded to non-home structure fires involving some type of electrical failure or malfunction accounted for an estimated annual average of 12 civilian deaths, 210 civilian injuries, and $614 million in direct property damage.”

The best way to prevent electrical fires is to inspect and maintain your wiring system. If trees are beginning to impede on wires coming into the building, call your electric provider immediately. Close all electrical boxes and panels; sometimes mice make comfortable homes in those nooks and crannies! Call in a professional electrician for any wiring repairs; remember, exposed spliced wiring is a huge fire hazard. Lastly, hook up all appliances and machinery in accordance with manufacturer recommendations. Use fuse protected power strips and industrial grade extension cords.

Fire Extinguishers

Just because fire extinguishers are bright red doesn’t mean they are the first thing on your mind when you’re checking things over. When is the last time you inspected your fire extinguishers?

According to OSHA, employers must:

Inspect, maintain, and test all portable fire extinguishers in the workplace. [29 CFR 1910.157(e)(1)]

Visually inspect portable extinguishers or hoses monthly. [29 CFR 1910.157(e)(2)]

Perform an annual maintenance check on portable fire extinguishers. Stored pressure extinguishers do not require an internal examination. Record the annual maintenance date and retain this record for one year after the last entry or the life of the shell, whichever is less. Make the record available to the Assistant Secretary upon request. [29 CFR 1910.157(e)(3)]

Empty and maintain dry chemical extinguishers (that require a 12-year hydrostatic test) every six years. Dry chemical extinguishers that have non-refillable disposable containers are exempt from this requirement. When recharging or hydrostatic testing is performed, the six-year requirement begins from that date. [29 CFR 1910.157(e)(4)]

Provide alternate equivalent protection when portable fire extinguishers are removed from service for maintenance and recharging. [29 CFR 1910.157(e)(5)]

Drainage Systems

If you have any waste streams coming from your facility, chances are you’ve had to obtain some sort of stormwater and/or wastewater permitting. Drainage systems are the ones doing the bulk of this work, so it’s important to keep up on them, even though they’re not the first thing on anybody’s mind.

Visually inspect and clear debris from drainage systems. Any retention basins and/or stormwater conveyance systems will help to reduce the risk of pollution and keep things running smoothly. For an exhaustive list of maintenance procedures for facilities drainage systems, visit this website.

Machine Efficiency

Failing machine efficiency might show up in your bottom line. Productivity might not be as high, your electrical bill might be creeping up, employees might be reporting repeated incidents. Any of these things can be signs that some or all of your machinery needs maintenance or a full replacement.

Visit the industrial hygiene section of our blog for more tips and tricks for improved efficiency and productivity.