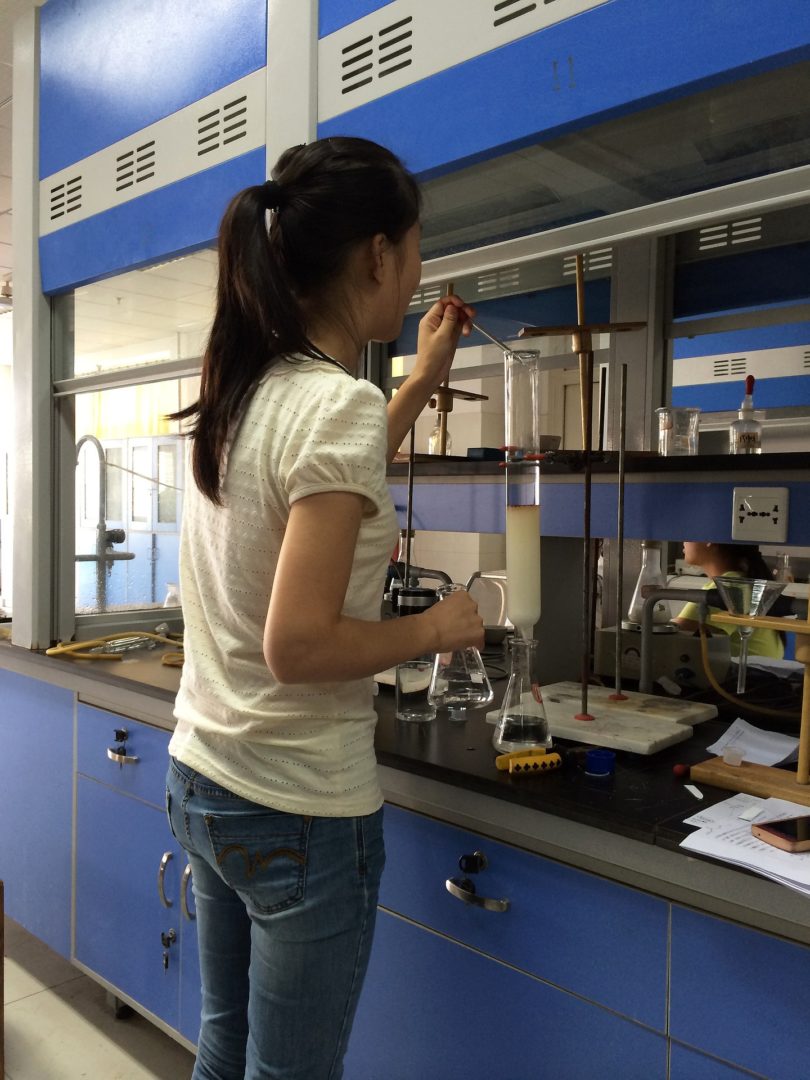

Labs are a risky environment. Between the sharp objects and beakers lined up in rows, workers have to constantly be aware of their surroundings. Personal protective equipment and other controls are part of what keep them safe, and fume hoods are no exception.

Fume hoods are an engineering control in labs, meaning they control the hazard. When scientists are working with dangerous materials that emit hazardous vapors, gas, and dust, a fume hood will move it away from their faces and out of the area through an exhaust system.

How often do fume hoods need maintenance?

Without getting too deep into the weeds about the inner workings of the mechanism, it’s essential that they are always in working order. Professionals should thoroughly inspect and document fume hoods on an annual basis. A quick visual inspection should be done every time it’s used. If there is any suspicion that a fume hood is not working correctly, it’s imperative to get in touch with someone ASAP.

Red flags

No air flow. A quick way to check to see if there’s air movement is to tape a piece of tissue to the sash. Turn on the hood. A tissue “flapping in the wind” is indicative of ample air movement – good news.

Weird noises. Occasionally, the fan or motor will need some TLC. Unusual noises are are good indicators to shut the hood down until it can be serviced.

Immediately tag the fume hood as “DO NOT USE” and contact the responsible party to get it repaired if any red flags arise.

Tag fume hoods as “DO NOT USE” if it has not been inspected in the past 12 months.

Temporarily decommissioning equipment can seem like overkill, but broken a fume hood puts lab workers at a high risk of exposure to dangerous fumes, dust, and vapors. By not maintaining (or even using) fume hoods, an essential safeguard is denied to workers.

Proper maintenance

Regular Maintenance/Use Guidelines

- Complete a visual inspection every time a fume hood is used

- Work at least 6″ into the machine

- Elevate equipment 2″ – 3″ above work surface to ensure proper air flow

Occasional Maintenance

Periodically clean:

- Sashes

- Hood surfaces

- Light panel

Annual Maintenance

Annual maintenance activities include:

- Lubricating parts

- Adjusting Belts

- Repairing fan blades

Manufacturer recommendations often point to specific things to be addressed annually. Specialists are available to conduct face velocity testing, smoke visualizations, and tracer gas tests.

Fume hoods are just like any other piece of equipment. They keep workers safe for years if they’re well taken care of. If you’re not sure that yours is working properly, promptly have it inspected by a professional.

TriMedia performs annual fume hood inspections. Contact us today for your free consultation.